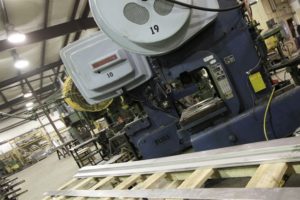

Supported by 17 presses with ton ratings of up to 250 tons, Bishop Metal Stamping’s compound die stamping services are used to manufacture products like drag chains, air filters, garbage can lid locks, and coining, serving the marine, automotive and industrial air filtration industries, as well as the disposal sector for municipalities. We will manufacture in quantities from 100 to 100,000 units, including short run production, and also accept contract manufacturing business.

Our presses run compound stamping operations with up to a 14 in. press stroke and 42 in. x 30 in. beds, and produces parts with thickness from 0.005 in. to 7 gauges, within a tolerance of +/- 0.005 in. Options for our stamping features include flat, heat treated, surface critical, tapped, and threaded stamping. Materials we work with include aluminum, copper, and ferrous metals, and we can finish products with drilling, tapping, plating or other surface operations. Contact Bishop Metal today to learn more about our capabilities.