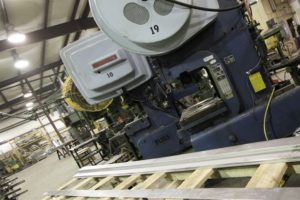

Using 5 head progressive dies and compound dies, Bishop Metal Stamping can fulfill your complex stamping requirements on our wide range of presses. We serve the marine, automotive, municipal disposal, and industrial air filtration industries, specializing in drag chains, garbage cans lid locks and truck mirrors.

Our in-house tool and die design shop can consult with you to develop the ideal configuration for your stamping job. We have expertise in special stamping features like countersunk, cruciform, surface and shape critical, and threaded stamping, as well as embossing, enameling, and coating. Each stamped part can be up to 20” in length by 20” in width, with a maximum diameter of 24”. We can produce parts as thin as .005”, up to a 7 gauge thickness.

To suit the material needs of your custom job, Bishop Metal Stamping works with stainless steel, aluminum, ferrous metals, and aluminum, along with a wide variety of other metals. We manufacture in runs from 100 to 100,000 units, and our press runs at up to 80 cycles/minute. Contact Bishop Metal Stamping today to inquire about your specific stamping requirements.