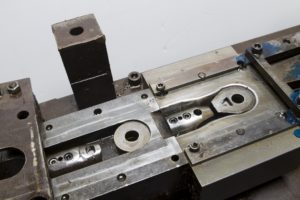

In support of our stamping operations, Bishop Metal Stamping provides tool and die design and manufacturing services for tooling for our presses up to 250 tons. Tooling can be fabricated up to 18 in. x 30 in. x 10 in., to tolerances of 0.001 in. Some of the die types that we manufacture include coining dies, blanking dies, swaging dies, and single hit, progressive, and transfer stamping dies. If tooling is required, we can produce checking, welding, assembly and inspection fixtures, as well as automation equipment.

Our tools and dies are typically used in stamping and production of drawn shells, pans, tubes, channels, and more. We offer a full line of services includes 2-D and 3-D CAD modeling, design and testing, prototyping, engineering, and inspection. We also provide tool history documentation and technical support. With the capacity to work in a wide variety of metals, from aluminum and bass to Kovar and titanium, we are sure to be able to meet all your needs.